Sustainability

Sustainability matters.

With our focus on children’s play spaces, we have a heightened awareness of the importance of daily practices that minimize our environmental footprint for future generations. We have always worked to reduce our ecological footprint but we now pledge to annually report on our sustainability initiatives and metrics.

2023 Highlights

One-for-One

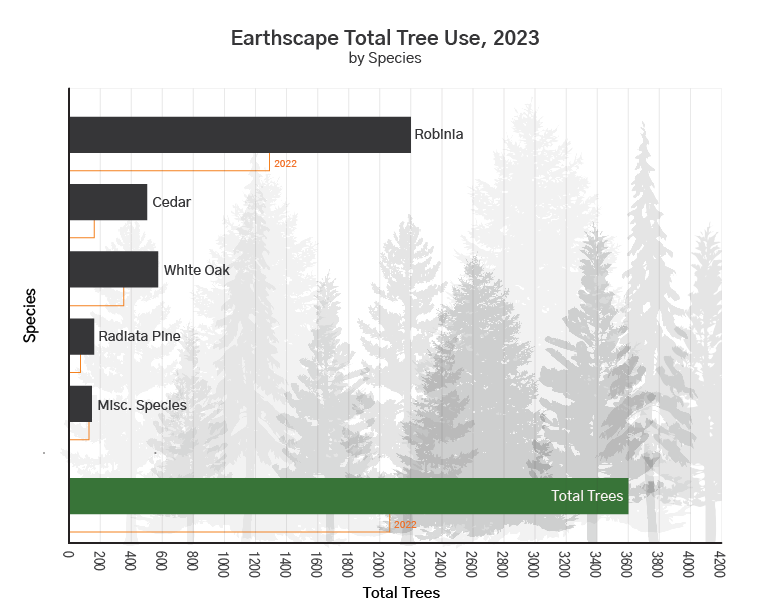

For every tree we use in our manufacturing, we plant at least one tree, either in a local habitat restoration project or through One Tree Planted, an international reforestation non-profit. This year we planted more than 9,395 trees.

Carbon Footprint Reduction

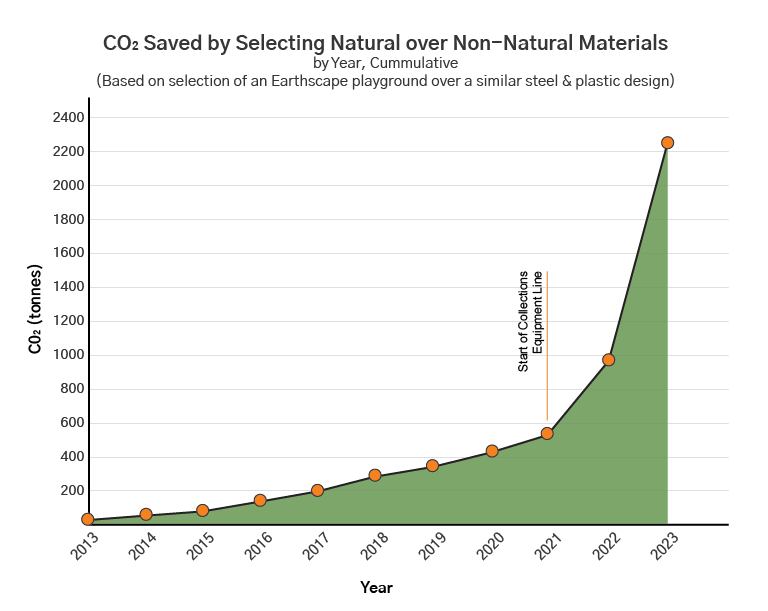

In 2023, we reduced our carbon footprint by 2230 tonnes (1128 in 2022) through material selection (wood versus plastic), reforestation initiatives, and waste re-purposing. In the Region of Waterloo, the average annual carbon footprint per capita is 7.9 tonnes. Thus, our efforts have offset the average carbon output of 306 people (142 in 2022).

Habitat Restoration

We are honoured to provide leadership to local habitat restoration projects that are returning wastelands to their original natural state. The first project, ‘The Habitats’, began construction in 2020. It will return 2.5 hectares of waste land to forest, prairie and wetland. Habitat restoration has many benefits: carbon capture, cooling of the urban environment, reduction of rainwater runoff, increasing the number and species richness of animals and plants, and public enjoyment of nature.

In 2022, we began a collaboration with Trees For Woolwich and Woolwich Township to plant more than 20,000 roadside trees over the next 10 years. In 2023, 4780 trees were planted along township roads in Woolwich.

Wood is Best for Sustainability

There are many reasons that we have chosen wood as our primary material – it is renewable, recyclable, has a low carbon footprint, and low embodied energy.

Wood is beautiful and versatile and healthy – not just the physical properties of it but there are psychological benefits too. Kids are healthier when they grow up in environments with natural materials.

Carbon Capture + Reduced Emissions

As the only significant renewable building material, wood is the best choice for a sustainable playground. Using wood for playgrounds reduces the carbon footprint both in terms of carbon storage and by avoiding greenhouse gas emissions.

As compared to the production of a plastic or metal playground, wood processing uses far less fossil fuel energy. In fact, wood makes up 47% of the raw material used in US manufacturing but uses only 4% of manufacturing energy. Every ton of wood that replaces another building material avoids 2.1 tons of carbon emissions.

Since 2013, the quantity of carbon dioxide that Earthscape saves by manufacturing with wood versus steel and plastic has increased each year.

original source: thinkwood.com/sustainability

Sustainably Sourced Wood

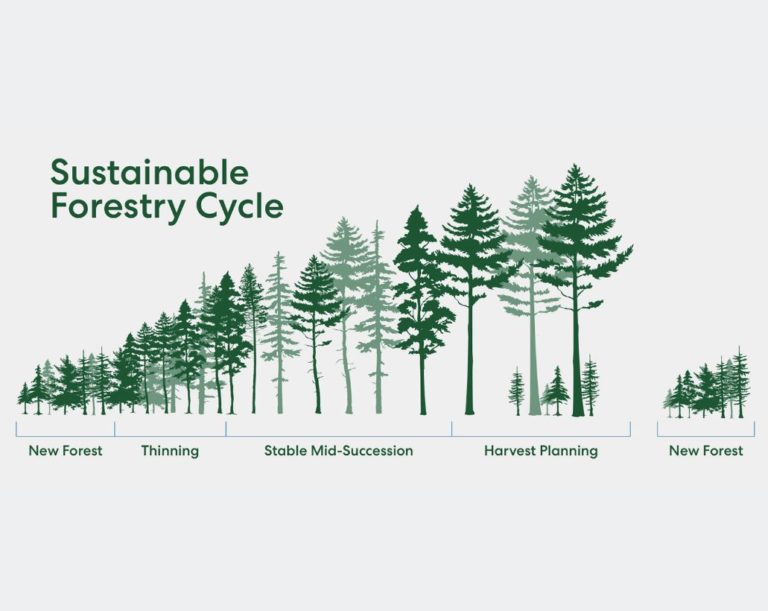

Wood is the most sustainable choice for playgrounds when it comes from a well-managed forest. Timber used in Earthscape playgrounds is sourced from: FSC certified sources, areas with extremely progressive forest practice codes, or small local timber suppliers.

Small suppliers do not operate at a scale that allows certification with large organizations like FSC or PEFC, but they are, in many cases more conscientious about caring for their land than certified suppliers. Each one operates under US and Canadian federal or state regulations requiring them to protect water quality, wildlife, and soil. In many cases the individual timber landowner has owned their property for generations and has a long-term land-use vision in mind.

Giving Back to Earth

ONE FOR ONE

Starting in 2020, Earthscape committed to planting at least one tree for every tree used in our production process. Through local reforestation initiatives (see below), and in partnership with One Tree Planted, a global reforestation non-profit, we track the number of trees used in production, and ensure we plant the same number of trees (or more!) in new forests.

Local Habitat Restoration Initiatives

Earthscape is providing ongoing technical leadership for several local habitat and reforestation projects with Trees for Woolwich. The largest of these is the Elmira Nature Reserve, an 18-hectare project within the City of Elmira. Thus far, 1000 trees have been planted and another 1000 trees are planned over the next 5 years.

By restoring rare habitats such as Oak Savanna and Tallgrass Prairie, endangered species will return to the area. ‘The Habitats’ is a second, 2.5-hectare project where abandoned farmland will be restored to include five endangered ecological land types.

The project is scheduled for completion in 2025. Earthscape is providing design, project management, financial support, construction equipment, as well as skilled construction labour.

In 2022, we began a collaboration with Trees For Woolwich and Woolwich Township to plant more than 20,000 roadside trees over the next 10 years. In 2023, 4780 trees were planted along township roads.

Our Efforts

Because our wood is already harvested from renewable resources, all trees planted are a net increase in trees planted every year. In 2023, Earthscape calculated our tree use at 3,600 trees and planted 9,395 trees in local and global forestation projects.

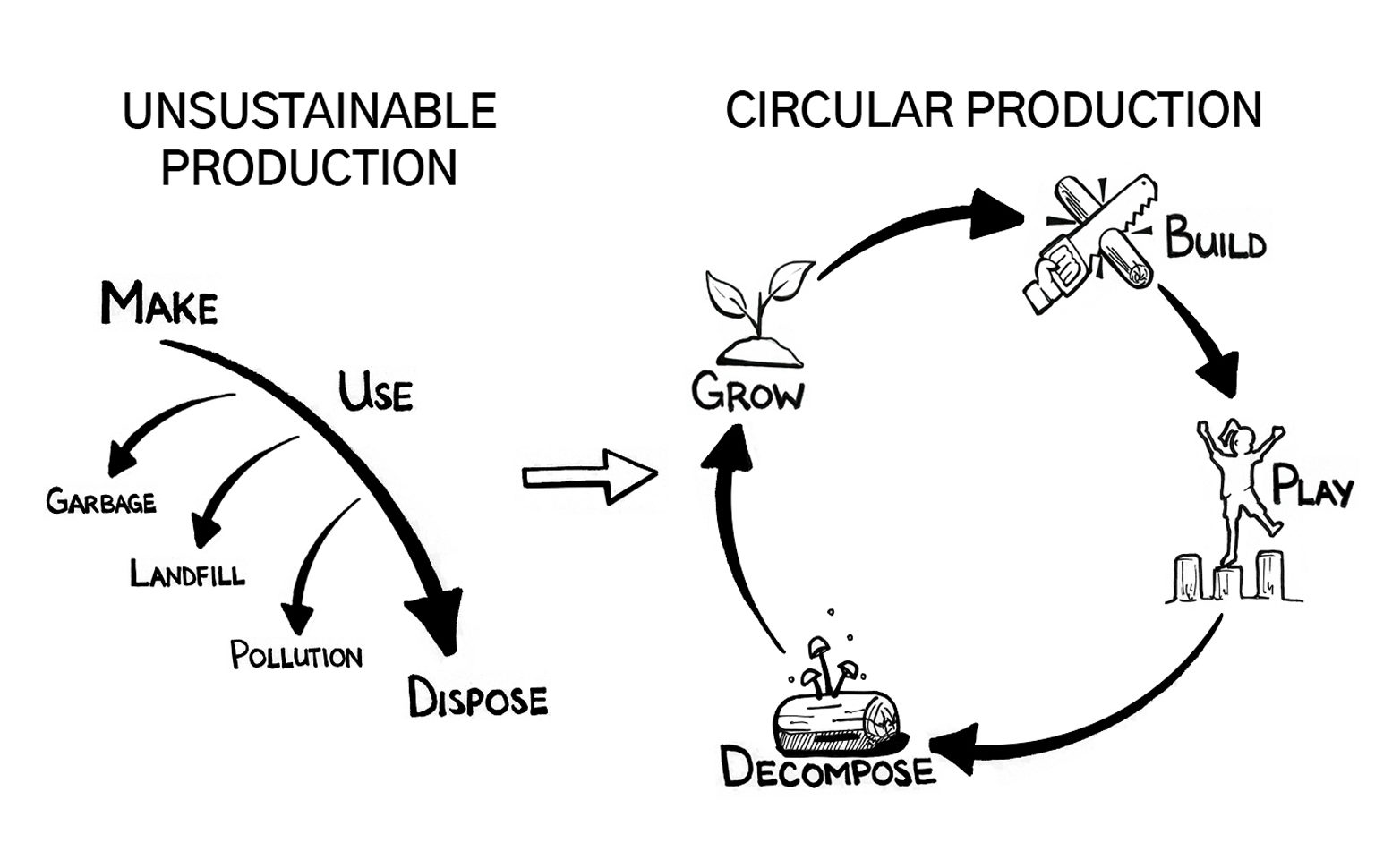

Cradle to Cradle Materials Management

While much of our current economy operates as linear – take, make, use and dispose – the circular economy (also called cradle to cradle) is restorative or regenerative. Here, manufactured products are designed for obsolescence and return their resources back to productive use at end-of-life.

The circular economy is modelled after another closed system we know well – Earth.

Sustainable production and consumption

Circular manufacturing is complex and challenging to implement. Based on our experience with Lean Manufacturing where the biggest production problems are solved first, we are tackling the most obvious waste and energy consumption issues and planning for continuous improvement.

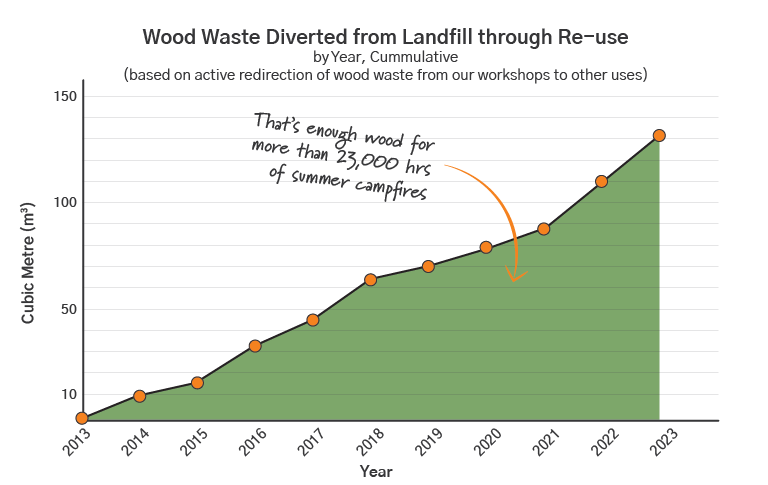

Increasing amounts of our wood waste is now being diverted to recycling

Since 2013 we have increased both the percentage, and the absolute amount of waste recycled. Rather than sending wood to landfill, we freely offer end cuts and unusable pieces to the community for use in hobby projects, for firewood or for other purposes.